The Guide to Success in Systems Integration in Industrial Automation

Welcome to our exploration of systems integration and the vital role it plays in industrial automation. Systems integration allows components and systems to seamlessly interact and function as a whole. Systems integration drives efficiencies to opimize operations and reduce costs, as well as encouraging innovative technological solutions to create new standards, functionality and quality. In this blog we will review the critical impact that systems integrators can have to help you enhance your operations and stay ahead of the competition.

The Critical Role of System Integrators in Industrial Automation

Industrial automation system integrators play a vital role in the successful implementation and optimization of automation technologies. System integrators are companies that specialize in systems integration to help clients meet their business and operational goals through industrial automation. They serve as the bridge between automation companies and end-users, ensuring that different systems and components work seamlessly together and function as a whole to achieve the desired outcomes. Here, we'll explore the core functions of system integrators and how they contribute to the overall success of an automation project.

Design and Engineering: System integrators bring their technical expertise to the table when designing and engineering automation solutions tailored to the unique requirements of a business. They consider factors such as production processes, equipment compatibility, and operational layout to create an efficient and effective system.

Project Management: Managing an industrial automation project requires a high level of organization and coordination. System integrators take charge of project management ensuring that all aspects of the project, from procurement to installation, are executed on time and within budget and meet business objectives.

Installation and Commissioning: System integrators are responsible for the installation and commissioning of automation equipment, ensuring that all components are correctly connected, calibrated, and functioning as intended. This process may involve configuring PLCs, setting up HMI interfaces, and integrating robotic systems.

Training and Support: To ensure a smooth transition to an automated environment, system integrators provide training and support for business personnel. They help operators understand how to interact with the new automation systems, troubleshoot issues, and maintain equipment to ensure optimal performance.

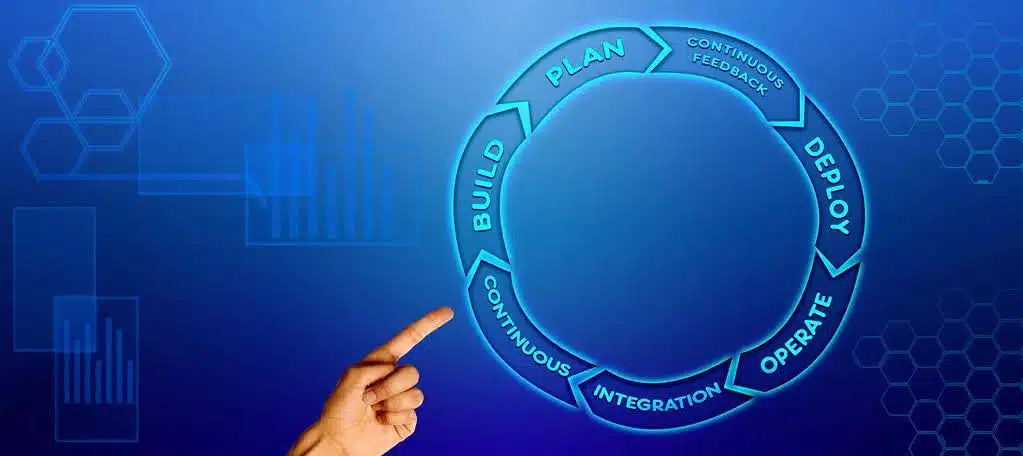

Continuous Improvement: System integrators maintain a relationship with their clients even after the project is completed, assisting with ongoing system improvements, updates, and expansions as needed. This support ensures that the automation system remains effective and efficient as the plant's needs evolve.

By leveraging the expertise and capabilities of system integrators, manufacturing plants can overcome the challenges associated with implementing industrial automation solutions and maximize the benefits of these advanced technologies.

The Power of Collaboration between Automation Companies and System Integrators

In order to successfully implement and maintain an industrial automation system, a strong partnership between a business and system integrator is crucial. This collaboration ensures that the client receives the best possible automation solution tailored to their specific needs. In this section, we'll explore how automation companies and system integrators work together to provide a comprehensive solution to meet business needs.

Identifying Client Needs: Both business and system integrators work closely with manufacturing plants to understand their unique requirements, production processes, and goals. This initial assessment helps them identify the most suitable automation technologies and strategies for the specific plant.

Developing Customized Solutions: Automation companies provide the components and technologies, while system integrators bring their expertise in designing and engineering custom automation solutions. By working together, they can create a system that is perfectly suited to the plant's needs, optimizing performance and efficiency.

Integration and Compatibility: With a multitude of automation components available in the market, ensuring seamless integration and compatibility is essential. Automation companies and system integrators collaborate to make sure that all components work together as a cohesive unit, minimizing the risk of system failure or performance issues.

Ongoing Support and Maintenance: A successful automation project doesn't end with the installation of the equipment. Automation companies and system integrators continue to work together to provide ongoing support, maintenance, and updates, ensuring that the system remains reliable and up-to-date with the latest technology advancements.

Knowledge Sharing and Industry Expertise: The partnership between automation companies and system integrators fosters an environment of knowledge sharing and collaboration. This synergy enables both parties to stay informed about the latest trends, innovations, and best practices in the industrial automation industry, ultimately benefiting the end users.

The collaboration between automation companies and system integrators is crucial for the successful implementation and optimization of industrial automation solutions. By working together, they can provide manufacturing plants with the most effective and efficient systems to help them stay competitive in the rapidly evolving industrial landscape.

Key Considerations for Choosing the Right System Integrator

The success of your industrial automation project largely depends on the system integrator you choose to work with. Selecting the right partner is crucial to ensure seamless integration, optimal performance, and long-term efficiency. In this section, we will discuss the key factors to consider when selecting a system integrator to maximize the success and potential of your automation investment.

Industry Expertise: Partnering with a system integrator who has a proven track record in your specific industry is essential. Their familiarity with the unique challenges, regulations, and requirements of your sector ensures they can design and implement solutions tailored to your needs. Assess their portfolio and inquire about their experience with projects similar to yours to gauge their industry expertise.

Technical Skills: It's crucial to verify the system integrator's technical expertise in working with the specific automation technologies you plan to implement. Ensure they have the technical skills that are required for the complexity of the project. This ensures they have the necessary skills and knowledge to implement and support the solutions you need. Request references or examples of past projects to evaluate their technical capabilities.

Vendor Relationships: A strong working relationship between the system integrator and automation equipment manufacturers can offer significant benefits. These relationships can lead to access to the latest technologies, better pricing, and quicker resolution of technical issues. Inquire about their partnerships with leading vendors to ensure they can provide you with the best possible solutions and support.

Adaptability: The ability to design scalable and adaptable solutions is a crucial attribute of a reliable system integrator. As your business evolves, your automation requirements may change, and your system integrator should be able to accommodate those changes. Discuss their approach to scalability and their flexibility in adjusting solutions to meet your changing needs.

By carefully considering these factors, you can make an informed decision when choosing a system integrator for your industrial automation project. The right partner will help you maximize the benefits of automation while minimizing potential challenges, ultimately contributing to the long-term success of your operations.

In Conclusion

Industrial automation system integrators play a crucial role in driving efficiency and innovation within the manufacturing industry.

In this blog we have discussed some key points which include:

- The pivotal role of system integrators in industrial automation, including design and engineering, project management, installation and commissioning, training and support, and continuous improvement.

- The power of collaboration between automation companies and system integrators in identifying client needs, developing customized solutions, ensuring integration and compatibility, and providing ongoing support and maintenance.

- Key considerations when choosing the right industrial automation system integrator, including industry expertise, technical skills, vendor relationships, and adaptability.

At Tri-Star Automation, we are dedicated to providing customized automation solutions that meet the unique needs of each of our clients. Our team of experienced system integrators brings technical expertise, industry knowledge, and a commitment to customer satisfaction to every project.

Contact us today to learn how we can help your manufacturing plant enhance its operations, stay ahead of the competition, and embrace the future of industrial automation.