How Robotics Systems Can Save You a FORTUNE On Labor Costs!

Thousands of companies across the globe are implementing advanced robotic systems to improve their business profit margins and add to their businesses efficiency. Every year many companies get left behind or become bankrupt by not staying ahead of their competitors.

They could have changed their futures by implementing advanced robotic systems into their production line.

In this short blog I’ll be explaining exactly how your business can directly benefit from robotic systems. I’ll also explain how important it is to implement robotic systems into your production line, as soon as possible.

How Do Robotics Systems Increase Productivity?

Employees involved in repetitive everyday workplace tasks (especially in production lines) can cause a lot of expensive mistakes! Mistakes happen often, so most businesses expense these errors and expect them to a certain extent. However, most companies are unaware of exactly how much money they are losing.

Employees often become complacent, tired, or make judgement errors that can cost you a fortune. These errors can happen every week, or every day...sometimes every hour. Usually workplace mistakes are minor expenses, but sometimes they’re massive catastrophic ones that can be a big negative hole in your company's profitability.

Reducing these costly errors is very important for improving your businesses overall bottom line!

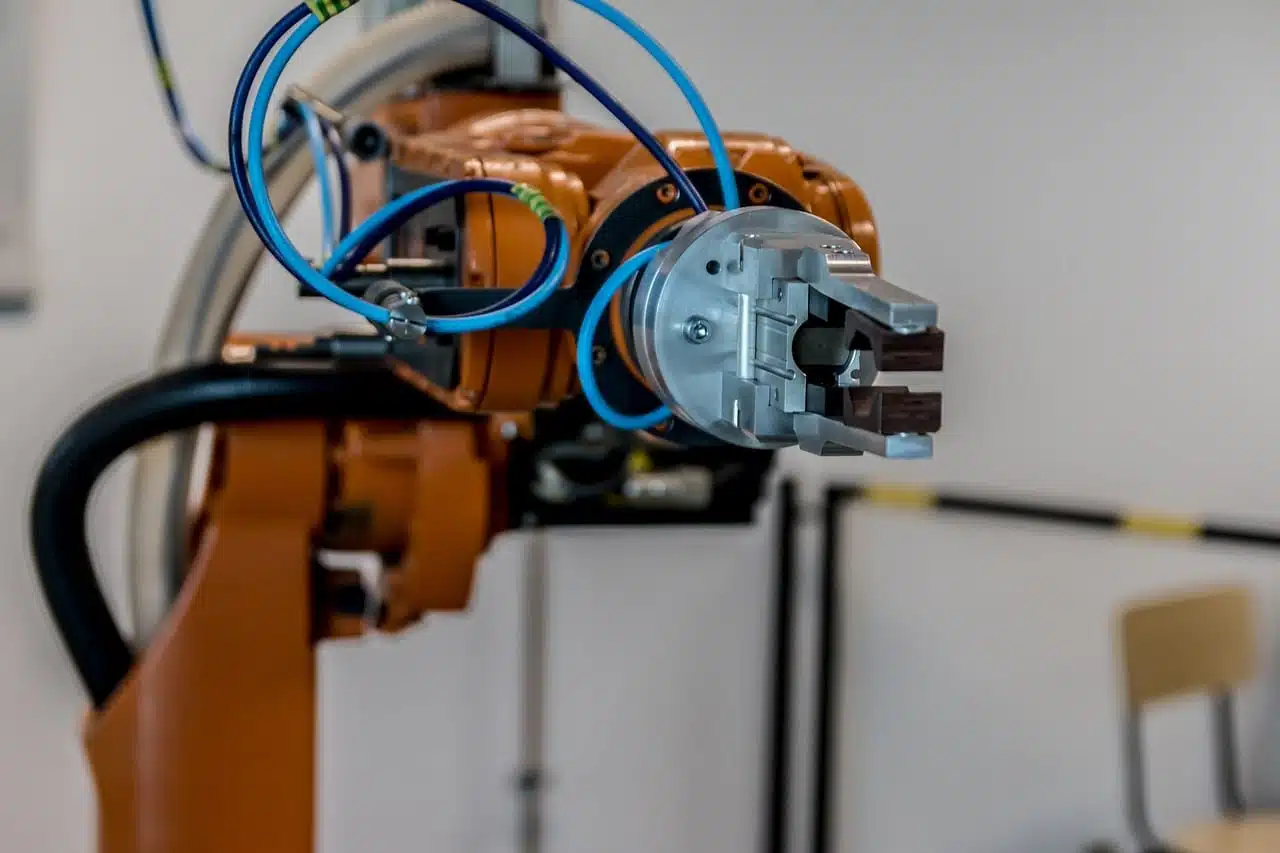

A robotic system can do many things for improving your business and production line including…

- Increasing Precision Accuracy (Less Human Error)

- Reducing Material And Component Waste

- Increasing Overall Production Output (Gets More Done Than Humans)

- Reducing Downtime

- And More!

Robotics systems can completely change a businesses overall revenue and efficiency, so it’s absolutely critical to implement these improvements as soon as possible.

How Do Robotics Systems Improve Production Lines?

In production/assembly lines, robotic systems can move faster and work with greater accuracy than humans. Accuracy also means less human error which can stall or hold up production lines. Not only are they more accurate, but you’ll produce more units at a reduced cost.

Robotic systems can also be programmed for production line changes, so businesses can quickly adapt to new product lines and various tedious specifications.

There are more robotic solutions today than we ever thought possible, and the creation of new and innovative robotic systems are being implemented and created as we speak.

So, if you have an idea for a robotics system or you need a solution to your business production problems, then it can be built and completely automated to your exact specifications!

Preventing Health And Safety Hazards With Robotics Systems

Robotics systems keep assembly lines and devices safe and clean! Robotics are often used for medical device assembly and pharmaceuticals. These companies often have heavy requirements for cleanliness, and require working environments safe from contaminants

Robotics systems can also be used to apply adhesives or substances too toxic for people to handle, which greatly reduces the potential health risks for staff and liability for businesses.

Robotics systems are also invaluable when used for inspections. Offshore oil rigs have been known to use robotic technology to inspect the rigs while people remain offshore.

There’s also applications of robotics systems handling dangerous chemicals or waste, while humans stay at a safe distance away from harm.

How Robotics Systems Reduce Workplace Liability

Human error can lead to dangerous workplace injuries and costly lawsuits from potential liabilities. By reducing human error and accidents you can also improve your companies overall safety record and ultimately reduce work injury claims.

Here’s how robotics systems can reduce potential liabilities in the workplace…

- By Lifting Heavy loads With No Injury

- Limiting Hazardous Areas (Low lighting, Chemicals, Heights)

- Limit Or Reduce Handling Of Toxic And Dangerous Chemicals And Adhesives

- Reduce Injury From Dangerous Production Line Items That Can Cut Or Dismember Employees

- Reduce Overall Operating and Equipment Accidents

- And Much More!

Reducing workplace accidents and liability claims not only makes your business safer for employees, but also boosts their moral, as well as saving you thousands in expenses!

Saving You Money Through Workplace Robotics Systems!

The cost to deploy a robotic system can seem like an expensive endeavour, however it’s one of the best business decisions you can make.

Most businesses see a positive ROI about ten to twelve months after implementing automation and robotics technology, once they do they really start to see their business soar to impressive heights.

In summary, here’s how your business can make money on robotics systems…

- Saves You Thousands In Employee Hourly Wages And Overtime

- Saves You In Liability And Legal Costs

- The System Improves Your Overall Business Production Line Product Output

- Reduces Material Waste With Improved Efficiency

- Get Real-Time Data Feedback For Robotic Systems Optimizations

- Improve The Overall Quality Of Goods Produced

Conclusion

Implementing high-tech robotics systems in your workplace will expand your business to new heights, and give you a BIG advantage against your competitors.

Not only will you improve workplace efficiency and reduce liability, but you’ll also save your business a lot of money!

If you’re looking to implement robotics systems in your workplace contact Tri-Star Automation for all your robotics system needs.